News

Middlewich Canal Breach

As you may have heard there has been a serious breach on the Middlewich Branch between Barbridge and Middlewich. This has closed the northern link between the Shropshire Union and the Trent and Mersey Canals which I had planned to use in August on the retur trip from Nantwich.

As you may have heard there has been a serious breach on the Middlewich Branch between Barbridge and Middlewich. This has closed the northern link between the Shropshire Union and the Trent and Mersey Canals which I had planned to use in August on the retur trip from Nantwich.

Given the size of the breach, and CRTs track record in dealing with these incidents ( e.g. Rufford Breach 2 years ago) I am doubtful that the canal will have reopened by August.

This is not a major issue as we can simply return down the Shropshire Union if needed. However it does open up a slightly unusual alternative route which is worth exploring.

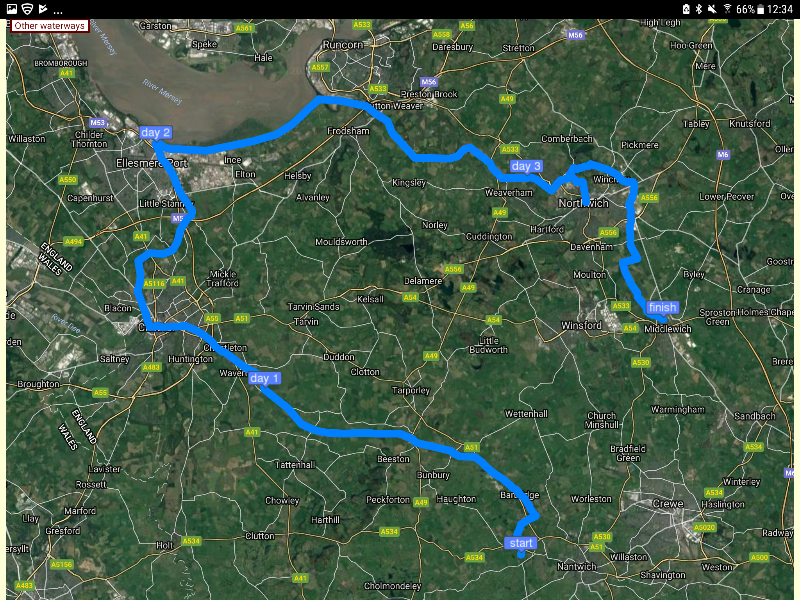

The alternative route is to travel north to Ellesmere Port and then out onto the Manchester Ship Canal heading East to the mouth of the River Weaver at Marsh Lock. Then head up the Weaver, probaly to Northwich before returning to Anderton and use the Boat Lift to get back onto the Trent and Mersey and head south as planned.

So if anyone is interested in some unusual cruising in August/September let me know.

2018 Winter works March Progress

The boat has been in the wet dock at Debdale for a few weeks and the joiner is working on the internal woodwork. Unfortunately progress is going to be little slower than originally planned due to the cold weather and one of the guys at Debdale breaking his leg leaving them short staffed, however there is no rush as long as things are finished to go to Crick in May.

To date the main front cabin has been relined with oak faced ply making it much smarter and lighter.

The kitchen work top on the starboard side has been shortened to match the port side. A new storage cabinet to house the wine boxes and radio is going in this corner.

The Table has been refitted with a small shelf above

On my last visit the joiner had installed the base of the TV unit, so my job was to run in the cables needed to connect the TV with the cabinet containing the sat receiver, Roku streamer, power , ariel etc and to put the power cable that will power it all in place

Winter 2017/18

Chelonian was built in 1994 and is now 23 years old so I thought it was about time it had some tlc to extend its life and improve some of the facilities. These works are being carried out over the winter in a number of stages.

Phase 1 November 2017

Hull and Fabrication works.

This included zinc coating the hull and several welding jobs to improve the hull life, as well as adding a new skin tank for engine cooling and a new flexiable drive coupling.

Full details here

Phase 2 January 2018

Exterior painting and internal Joinery

Full details here

Hybrid Upgrade winter/spring 2018

Upgrading the Hybrid system with a new Control Box and a new water cooled motor.

Full details here

Other works

Internal Painting, some woodwork and changes to safety system including fitting a Man Overboard System.

Full details will appear here

2017 The Year in Summary

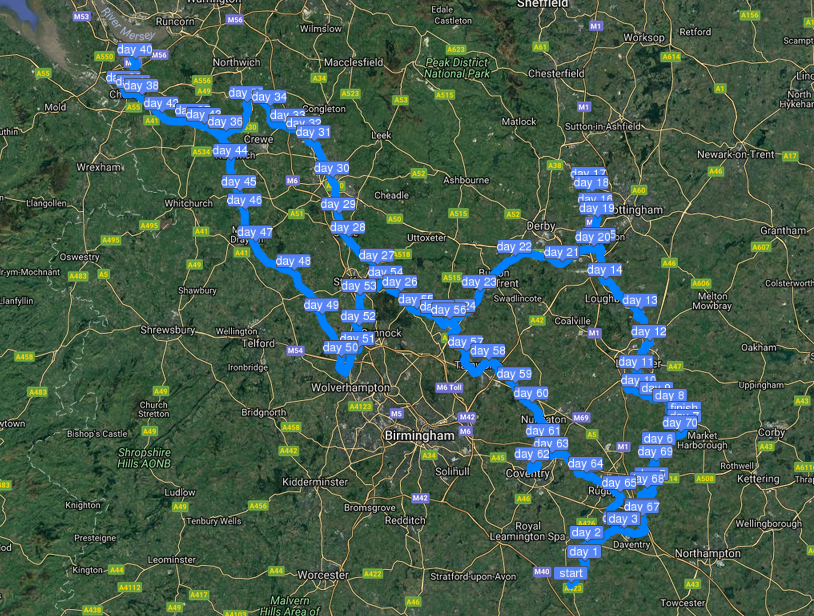

This year we started in May with a short trip from Fenny Marina to Crick for the Boat show over the late May Bank Holiday weekend before heading north through Leicester to explore the Erewash Canal to Langley Mill. Returning to the River Trent and continuing north on the Trent and Mersey to Middlewich and then West to Barbridge and join the Shropshire Union and continuing north to Chester and on to Elesemere Port. From Elesemere port returning south via the Shropshire Union to Autherly Junction and the Staffs and Worcs Canal to Great Haywood, South to Fradley to join the Coventry Canal all the way to Coventry then onto the Oxford Canal to Braunston and return north via Crick to the new mooring at Debdale Wharf.

In total we completed 445 miles and 296 locks in 250 hours of cruising over 76 days, averaging just under 3 lock MPH and just under 10 lock miles per day. We used The 435liters of diesel fuel, with an estimated 75L being used by boiler and the remaining 360L by the engine for propulsion. The engine ran for 114hours (3.1 L/hr for engine hours, or 1.4 L/hr overall) with the rest being on the electric drive. Also during this time we used 500KWhr of Domestic Electricity with 150KWhr coming from the Solar Panels and the balance generated by the hybrid system.

Winter works 2016/17

So now back know the home mooring and I can start the list of jobs over the winter. One thing you can be sure off is nothing ever fixes itself so over the summer I have accumulated a list of around 20 jobs that need doing thus winter. As next year (April) is also time for the boat safety inspection some of the jobs will need to be prioritised.

So now back know the home mooring and I can start the list of jobs over the winter. One thing you can be sure off is nothing ever fixes itself so over the summer I have accumulated a list of around 20 jobs that need doing thus winter. As next year (April) is also time for the boat safety inspection some of the jobs will need to be prioritised.

It is also time for the boat to be blacked, and after investigating options I have put a deposit down on a slot to have the hull "zinc sprayed" at Debdale Wharf next November this should reduce the ongoing maintenance on the hull for up to 10 years and save money in the long term.

Two weeks ago I visited the boat to make a start on the jobs, by replacing the exhaust on  the deisel boiler, only to find that there was a leak into one of the lockers and cupboard in the engine room. As both the engine and central heating pipes how through thus area it was not immediately clear which was leaking, or how the water could have spread as far as it did rather than just dropping just to the bilge. The wet locker has been emptied and left open to dry out ( a slow process at this time of year) and I ran the engine for an hour without any sign if a leak.

the deisel boiler, only to find that there was a leak into one of the lockers and cupboard in the engine room. As both the engine and central heating pipes how through thus area it was not immediately clear which was leaking, or how the water could have spread as far as it did rather than just dropping just to the bilge. The wet locker has been emptied and left open to dry out ( a slow process at this time of year) and I ran the engine for an hour without any sign if a leak.

This weekend I returned to the boat and managed to get the boiler exhaust replaced and the air intake installed. The original exhaust was supplied as part of the boiler "kit" and includes a long silencer tube. This meant that the exhaust looped around in the engine compartment and sat on the top of the counter where it soaked up any water or oil, which then burns off the exhaust producing lots of potentially flammable fumes. The new exhaust is much shorter with a compact silencer and is mounted so that is held clear of the counter and lining. This along with the new air filter/intake now mounted inside the engine compartment rather than the bottom if the locker, means that the boiler is quieter in the cabin. One last bit is to lag the silencer and aluminium tape over the lagging to keep any splashes of water oil etc off.

1 job down 18 to go.